CNC Glass Machining Services for High-Precision & Customization

Glass CNC Machining: The Ultimate Art of Precision Crafting

In the modern world, where accuracy and individuality become the key factors for manufacturing, glass CNC machining has become one of the breakthrough technologies. From precise and complex optical parts to unique glass patterns, CNC machining gives us a whole different way of dealing with glass. This article will explore the specifics of CNC machining, the steps in the process, the uses of its applications, and the benefits of the technology as your go-to guide to a key contemporary technology.

What is Glass CNC Machining?

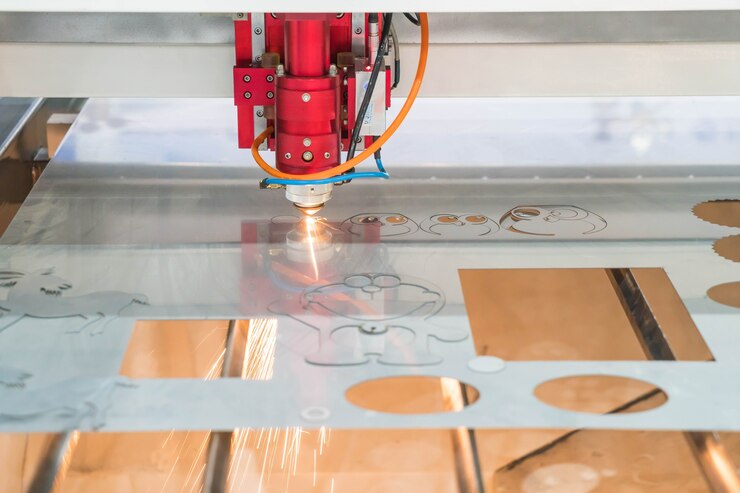

Glass CNC machining is the process of cutting, shearing, boring, engraving, and planning glass with the use of computer numerical control machines. These machines come with the best programming that makes them produce highly accurate outputs that match the envisioned design. This technology has been adopted in many different fields such as optics, electronics, construction, and custom manufacturing. Originally developed as an additive technique that then paired automation with precision tools, CNC machining has emerged as the best way to work with glass.

How Does Glass CNC Machining Effectively Happen?

Design Phase: The first step involves designing on the computer with Picture and modeling software known as CAD (Computer-Aided Design). In essence, this file is the machining blueprint hence the name, and will position our company to respond effectively to any market trend.

Machine Setup: It is accompanied by tools such as a diamond-tipped cutter, drill, and engraver for Glass work.

Execution: The mechanically controlled tool acts upon the structure and pattern that was set and proceeds to either shape or break the glass seamlessly.

Finishing: After machining the glass it undergoes other finishing processes such as polishing or any other form of coating to give it the appearance desired.

Pros of Glass CNC Machining

High Precision: CNC machines can come to a level of accuracy of 0.01mm which is rather good.

Versatility: The application of CNC ranges from cutting and drilling to engraving and even a milling operation.

Cost-Effectiveness: It can be understood that CNC machining reduces costs because of the reduced wastage of materials and minimum use of manpower.

Customization: Computer-aided manufacturing technology used in CNC allows for the development of unique product designs that may meet the needs of a client.

Consistency: CNC machines save time because once programmed they can reproduce a design with precision making them suitable for use in large-scale production.

Why CNC Glass Engraving Machines are Ideal for Glass CNC Machining?

CNC Glass Engraving Machines are some of the most accurate and efficient engineering technologies available for cutting glass CNC. These complex devices have come to define the manner in which most speedy and accurate designs perfect their surface, thus becoming the key and reliable equipment in each field requiring accuracy, durability, and excellent finish work. Here’s why they are the ideal solution for glass CNC machining:

Perfect Fit Finish for Complex Fabrics

CNC Glass Engraving Machines come with modern technology for accuracy, which is suitable for developing diverse designs, angles, curves, and carving. These devices work perfectly even when it comes to custom design, logos, or detailed artwork on any t-shirt or fabric. The accuracy is also determined by the combination of high-power spindles and control systems that ensure the reliability of operations in cutting complicated designs.

Prepared with Advanced Automation for Higher Efficiency

The machines are designed to prevent human interjections and enhance work processes. Some of the characteristics familiar to CNC Glass Engraving Machines include self-organization of the tools and vacuum systems ensuring secure placement of the glass. Besides the speed increase, the errors are also reduced and they are ideal for large production projects or complex projects.

Additional Features Specific to Enhanced Operation

Modern CNC Glass Engraving Machines are packed with innovative features that set them apart:

• Hiding Tool Library: Prevents tools from rusting and thus can guarantee longer service for tools used in water treatment.

• Automatic Contraction Door: Reduce the cumbersome nature of handling glass, improving the ease of use and safe handling of glass for users.

• Vacuum Aluminum System: Specifically, it features ways of averting freezing and blocking, thereby guaranteeing continuous operations in challenging surroundings.

• Cooling Water Sealing System: Specific inventions that help to enhance the cooling operation; ability to maintain the appropriate temperature within the working of the machine.

Sustainable/Environmentally Friendly and Whole Price

CNC Glass Engraving Machines with sustainability factor included in their make. They made their products versatile with the regular options of cutting, engraving, welding, etching, milling, and that is not all, by offering accurate results in one operation and thereby reducing the wastage of material making it economical.

User-Friendly Operation

These machines are very easy to operate due to enhanced features such as wireless hand remotes and efficiency control panels. By remote programming and supervising of the machining operations the operators can effectively and efficiently handle the system by removing the need for extensive training.

Superior Surfaces for Marketing Edge

One of the excellent advantages that are attributable to CNC Glass Engraving Machines is the heightened POLISH that is associated with this machinery. The remains in engraving that go straight to carving and polishing guarantee that every product is of the best quality. This capability is especially useful to companies that need to create competitive advantages in their respective industries.

Why Choose BAINENG CNC Glass Engraving Machines?

With pride, at BAINENG CNC, our CNC Glass Engraving Machines are designed in a unique way due to enhanced performance. Each part is designed with the primary aim of achieving the best results and ranges from high-power spindles to patented cooling systems. Professionals in various industries use our machines because of their efficiency, precision, and ability to work hard in cases that require high-capacity work.

Selection Criteria for Glass CNC Machine

When selecting a CNC machine for glass machining, consider the following factors:

Tooling Compatibility: The machines ought to incorporate the use of diamond-tipped tools for glass machining.

Precision Capabilities: Make sure that the machine has precise programming for intricate structures as recommended.

Material Handling: It is useful to select equipment for working with different kinds of glass that can be, for example, tempered, borosilicate, and acrylic.

Ease of Use: The ease of use of interfaces simplifies its programming as well as its use.

New Development in the Glass CNC Machining

CNC machining of glass as a field is still fresh and developing. Recent advancements include:

• Automated Tool Changers: Enabling tools changed to occur automatically to minimize the need to stop the process in between, to save time.

• Real-Time Monitoring: Higher-level sensor systems monitor the whole process of machining and avoid mistakes.

• Eco-Friendly Practices: Present-day facilities require less water and energy as compared to the previous ones.

Tips for Optimizing CNC Machining for Glass

Use the Right Tools: For using glass for carving or simple cutting it requires tools with diamond tips only.

Monitor Speeds: Some works could require changing the speed of the spindle in order to avoid cracking or chipping.

Cooling Systems: To hold the glass at the right temperature, you should try using water or air cooling on the tools.

Regular Maintenance: It is important that in order to get good results, your CNC machine is always in good condition.

Conclusion

With its ability to deliver precision, efficiency, and versatility, glass CNC machining is setting new standards in manufacturing. From high-precision glass drilling to creating custom glass parts, the applications are virtually limitless. As technology continues to advance, the capabilities of CNC machines will only expand, making them indispensable across industries.