Comprehensive Guide to CNC 2D Glass Engraving Machines

CNC (Computer Numerical Control) 2D glass engraving machines have become an integral part of modern manufacturing, particularly in industries that require precision and intricate designs. These machines, known for their ability to engrave complex patterns and text onto glass surfaces, offer a range of benefits that make them indispensable. This guide will provide an in-depth look at CNC 2D glass engraving machines, covering their features, benefits, applications, and market trends.

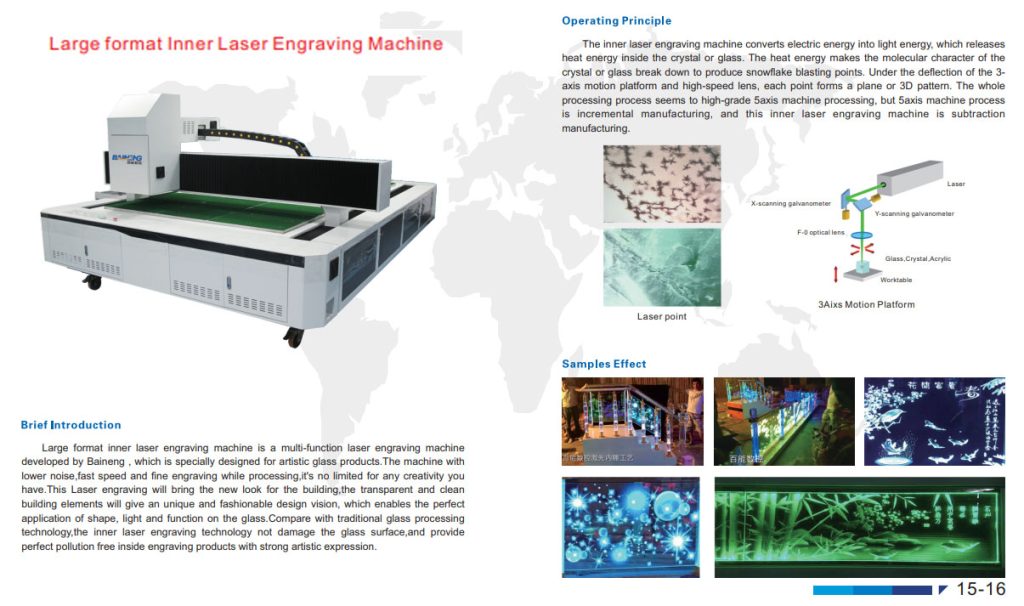

A CNC 2D glass engraving machine is a specialized piece of equipment designed to engrave two-dimensional designs onto glass surfaces. Unlike 3D engraving machines, which can create depth and texture, 2D engraving machines focus on creating flat, intricate designs with high precision. These machines use computer technology to control the engraving process, ensuring consistent and accurate results.

What is a CNC 2D Glass Engraving Machine?

Key Features of CNC 2D Glass Engraving Machines

High Precision and Accuracy

One of the standout features of CNC 2D glass engraving machines is their high precision and accuracy. The computer-controlled system ensures that each engraving is executed with exactitude, making it possible to create detailed designs that are consistent across multiple pieces.

User-Friendly Software

CNC 2D glass engraving machines come equipped with user-friendly software that allows operators to design, edit, and execute engravings with ease. The software typically supports various file formats, making it easy to import designs from popular graphic design programs.

Robust Construction

These machines are built with robust materials to ensure durability and longevity. The construction typically includes a sturdy frame, high-quality engraving tools, and reliable motors that can withstand continuous use.

Versatility in Design

CNC 2D glass engraving machines can handle a wide range of design complexities. From simple text to intricate patterns, these machines can reproduce detailed designs with ease. This versatility makes them suitable for a variety of applications across different industries.

Automation and Efficiency

Automation is a key feature of CNC 2D glass engraving machines. The automated process reduces the need for manual intervention, minimizing the risk of errors and increasing overall efficiency. The machines can operate continuously, which is ideal for high-volume production runs.

Benefits of CNC 2D Glass Engraving Machines

Enhanced Productivity

The automation and precision of CNC 2D glass engraving machines significantly enhance productivity. These machines can produce a large number of engraved pieces in a short amount of time, making them ideal for businesses that need to meet high demand.

Cost-Effective Production

While the initial investment in a CNC 2D glass engraving machine can be substantial, the long-term benefits outweigh the costs. The efficiency and reduced labor requirements lead to cost savings over time. Additionally, the high precision of these machines reduces material wastage, contributing to cost-effective production.

Consistent Quality

CNC 2D glass engraving machines ensure that each piece produced is of consistent quality. This consistency is crucial for maintaining high standards in production and meeting customer expectations. The improved quality also enhances the overall aesthetics and functionality of the final product.

Customization Capabilities

These machines offer enhanced customization capabilities, allowing businesses to produce unique and personalized products. This is particularly valuable in industries such as architecture and interior design, where customized glass elements are in high demand.

Applications of CNC 2D Glass Engraving Machines

Architectural and Interior Design

In the field of architecture and interior design, CNC 2D glass engraving machines are used to create decorative glass panels, partitions, doors, and windows. These machines allow designers to incorporate intricate patterns and designs into glass elements, adding a touch of elegance and sophistication to buildings and interiors.

Automotive Industry

The automotive industry uses CNC 2D glass engraving machines to engrave logos, patterns, and functional elements onto glass components such as windows and mirrors. The precision and consistency of these machines ensure that each component meets the stringent quality standards required in the automotive sector.

Consumer Electronics

CNC 2D glass engraving machines are employed in the consumer electronics industry to engrave logos, labels, and decorative elements onto glass surfaces of electronic devices. This application is particularly relevant for high-end consumer goods where aesthetics and branding are important.

Art and Craft

Artists and artisans use CNC 2D glass engraving machines to create intricate and detailed designs on glass art pieces. The precision and versatility of these machines enable artists to bring their creative visions to life with unparalleled accuracy.

Signage and Branding

Businesses use CNC 2D glass engraving machines to create high-quality signage and branding materials. The ability to produce detailed and eye-catching designs on glass makes these machines ideal for creating signs, plaques, and promotional items.

Market Trends and Developments

Increasing Demand for Customization

There is a growing demand for customized and personalized products across various industries. CNC 2D glass engraving machines cater to this demand by enabling the production of unique and customized designs. This trend is particularly evident in the architecture, interior design, and consumer goods sectors.

Technological Advancements

Continuous advancements in CNC technology are driving the development of more sophisticated and efficient 2D glass engraving machines. Innovations such as improved software, higher precision, and faster processing speeds are enhancing the capabilities of these machines, making them more attractive to manufacturers.

Expanding Applications

The versatility and benefits of CNC 2D glass engraving machines are leading to their increased adoption across different industries. From automotive to electronics and art, more sectors are recognizing the value of these machines in improving productivity, quality, and design capabilities.

Focus on Sustainability

Sustainability is becoming a key consideration in manufacturing processes. CNC 2D glass engraving machines contribute to sustainability by reducing material wastage and energy consumption. Manufacturers are increasingly investing in these machines to align with their sustainability goals.

Conclusion

CNC 2D glass engraving machines have revolutionized the way glass is engraved, offering unmatched precision, versatility, and efficiency. These machines are becoming increasingly popular in China, driven by advancements in technology and the growing demand for customized products. Whether in architecture, automotive, electronics, or art, CNC 2D glass engraving machines are playing a pivotal role in enhancing design capabilities and improving production quality. As technology continues to evolve, the future of CNC 2D glass engraving machines looks promising, with new opportunities and applications on the horizon.