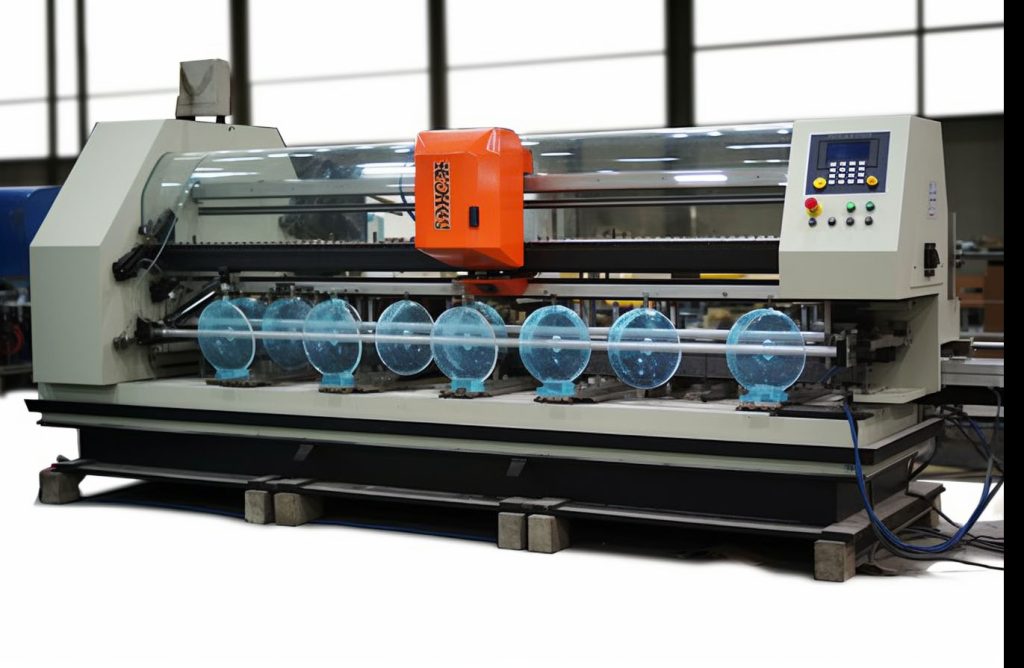

Precision CNC Glass Etching Machine for Intricate Designs and High Efficiency

CNC glass etching machines are advanced tools designed for precise and intricate etching on glass surfaces. These machines use computer numerical control (CNC) technology to automate and control the etching process, ensuring high precision and consistency. Here’s a comprehensive product solution for CNC glass etching machines, covering their features, applications, benefits, and considerations for choosing the right machine.

Key Features of CNC Glass Etching Machines

High Precision and Accuracy

CNC glass etching machines are renowned for their high precision and accuracy. The CNC technology allows for the detailed and intricate etching of patterns, logos, text, and images on glass surfaces with exact measurements and minimal error.

Automation and Efficiency

These machines are fully automated, which significantly enhances productivity and efficiency. The automation reduces manual intervention, allowing for continuous operation and the ability to handle large volumes of work with consistent quality.

Versatility

CNC glass etching machines can work on various types of glass, including tempered, laminated, and coated glass. This versatility makes them suitable for a wide range of applications, from decorative items to functional components.

User-Friendly Interface

Modern CNC glass etching machines come with user-friendly interfaces, often featuring touchscreens and intuitive software. This allows operators to easily program designs, adjust settings, and monitor the etching process.

Customization Capabilities

The machines offer extensive customization capabilities, enabling the creation of unique and personalized designs. Users can upload custom patterns or select from pre-programmed templates, allowing for diverse and creative etching options.

Applications of CNC Glass Etching Machines

Decorative Arts and Crafts

Artists and designers use CNC glass etching machines to create intricate and beautiful designs on glassware, vases, and decorative panels. The precision and detail achievable with these machines make them ideal for high-quality decorative pieces.

Architectural Elements

In architecture, CNC glass etching is used to produce custom windows, doors, partitions, and facades. The ability to etch complex patterns and images adds aesthetic value and uniqueness to architectural projects.

Signage and Branding

Businesses use CNC glass etching machines to create branded glass signage, logos, and promotional items. The precision of CNC technology ensures that branding elements are clear, detailed, and professional-looking.

Awards and Trophies

CNC glass etching is commonly used in the production of awards and trophies. The ability to etch detailed text and logos enhances the elegance and prestige of these items.

Electronics and Appliances

In the electronics industry, CNC glass etching is used to produce glass components for devices such as screens, panels, and protective covers. The precision etching ensures that these components fit perfectly and function as intended.

Benefits of Using CNC Glass Etching Machines

Enhanced Product Quality

The precision and consistency provided by CNC glass etching machines result in high-quality products. The ability to produce detailed and intricate designs enhances the aesthetic and functional value of etched glass items.

Increased Efficiency

Automation in CNC glass etching machines significantly increases production efficiency. The machines can operate continuously, reducing the time required for each project and increasing overall output.

Cost-Effectiveness

While the initial investment in CNC glass etching machines can be substantial, the long-term benefits include reduced labor costs, increased productivity, and lower material waste. These factors contribute to overall cost savings.

Flexibility and Customization

CNC glass etching machines offer a high degree of flexibility and customization. This allows manufacturers to cater to specific customer needs and create unique, personalized designs, adding value to their products.

Choosing the Right CNC Glass Etching Machine

Assessing Your Needs

When selecting a CNC glass etching machine, it is essential to assess your specific needs and requirements. Consider factors such as the types of glass you will be working with, the complexity of designs, and the volume of production.

Budget Considerations

Budget is a crucial factor in choosing the right machine. While fully automated CNC machines offer the highest efficiency and precision, they also come with a higher price tag. Balance the cost with the features and capabilities you need.

Evaluating Machine Features

Evaluate the features of different CNC glass etching machines, including the level of precision, automation capabilities, user interface, and customization options. Ensure that the machine you choose can meet your production demands and quality standards.

Supplier Reputation

Choose a reputable supplier or manufacturer with a proven track record of providing high-quality CNC glass etching machines. Look for companies that offer reliable customer support, training, and maintenance services.

Conclusion

CNC glass etching machines are indispensable tools in the glass processing industry, offering high precision, efficiency, and versatility. These machines cater to a wide range of applications, from decorative arts and crafts to architectural elements and electronic components. By choosing the right CNC glass etching machine, manufacturers can enhance their productivity, reduce costs, and produce high-quality, customized glass products that meet the demands of today’s market.