CNC Glass Grinding Machine:High-Precision Glass Processing

The Solution that Makes Glass Workable: 5-Axis Glass Beveling Machine

Among precision glass processing, the 5 Axis Glass Beveling Machine is the most revolutionary. This CNC glass grinding machine is specifically for glass edge processing, and it has top quality therefore is suitable for architectural and automotive glass industries and for industrial glass manufacturers. Based on its features and construction, the 5 Axis CNC glass grinders can provide a higher level of performance which can effectively address various requirements of glass fabrication today.

Efficient Glass Processing for Enhanced Productivity

However, one of the unique features of the 5 Axis CNC glass grinding machine is the ease of clamping and positioning of the glass. This machine is used for roughing, a second for fine grinding and polishing respectively; using this single machine greatly increases working efficiency. This is especially useful when working with nonstandard shapes of glass since it is necessary to make multiple settings on the tool. Since each glass is accurately and efficiently cut, produced, and shaped through the CNC glass edge grinding machine then the chances of making a mistake or holding back on the workflow of the entire production are greatly minimized.

Complex CAM Software for Enhanced Operating Processes

The 5-axis CNC glass beveling machine means that there is effective CAM Software that can directly convert CAD designs into processing files. On the basis of the program, these one-step operators enable the creation of processing files for distinct and difficult glass designs to operate. For that matter, the developed software is user-friendly so that even those new to automated glass processing can easily learn how the software works and thus requires minimal training time.

Effective Utilization of Tools in Improvement Projects

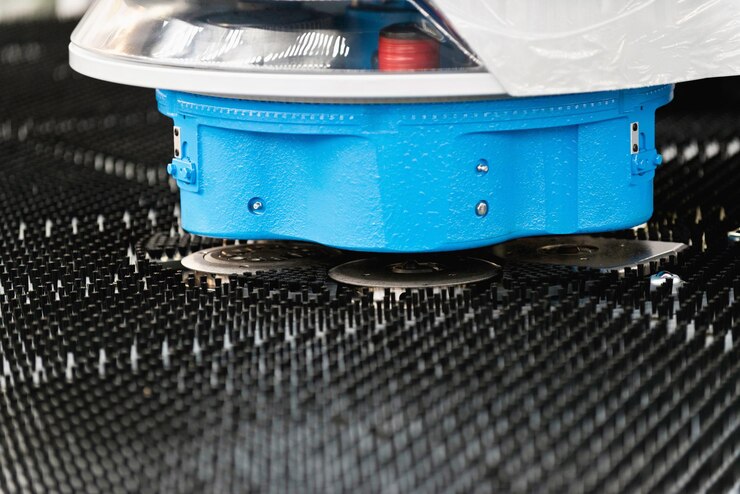

The 5-axis CNC glass polishing machine is designed as an integrated device that incorporates four functional heads. These heads can swivel in as little as 0.3 seconds, allowing the machine the capacity to change over from one task to another. Any angle processing is made possible by the chosen axis, and this makes the device suitable for the creation of different levels of architectural glass, automotive glass, and fancy glass.

Further, the machine has other high-quality features like arc sources and rectangular planar arc sources that provide uniform plasma density coupled with stable reactivity. This in turn ensures a slim layer of film with high cohesion force, high hardness, and surface uniformity which is very suitable for producing elegant and robust glass edges.

Customized Machining of Seamless Angles for Every Industry

However, no matter which type of glass it is, whether architectural glass, fancy glass, or industrial glass, the 5 Axis CNC glass beveling machine will bevel with high precision. The CNC glass grinding machine receives high-precision grinding wheels and an intelligent control system to guarantee the beveled perimeters in every glass processed are uniform. In a single run, the machine is in a position to create progressive bevel forms such as straight, round, and polygonal bevels hence versatility.

Automation of New Robotic Functions

The CNC glass beveling machine is equipped with the newest automatic control system, built-in the one-touch start function as well as optimum path selection function. Thus, we have the following robotic features that ensure that the machine operates as it is programmed with little supervision. The control of the system also minimizes on human interface and produces constant outcomes that can be useful in large-scale production.

An Ideology of Environmentally Friendly and Customer-Friendly Layout

The 5 Axis CNC glass beveling machine has an environmentally friendly layout optimizing the space and minimum energy use. The front side control panel has a touch screen that enables the operators to control the processing activity and manage the stages of the equipment. This type of design relieves the operators’ fatigue and improves the efficiency of the entire process of glass processing, thus improving the overall quality of the glass.

Reliability and Steadiness for the Life-Cycle of a Commodity

Reliability might be of central importance when choosing between different mechanical equipment used in industries. The 5-axis CNC glass beveling machine is manufactured using high-grade components such that the product being developed is durable and possesses mechanical strength. There is tough and resistant equipment used on a constant basis and tough working conditions to offer the best performance and durability. The mechanical structure is very sound, and will not flex during use, even when subjected to weights; hence, there will be no variation each time the machine is used.

Why 5-Axis Glass Beveling Machine is Suitable for CNC Glass Grinding Machines?

Designed for the CNC glass grinding machine, the 5 Axis Glass Beveling Machine is a sophisticated system suitable for a wide range of applications due to enhanced accuracy and high performance. Able to perform high-quality beveling, with complex glass shapes without an issue providing perfect edge all the time. This machine is useful in automotive glass and even architectural glass, as well as in making tempered glass, as it yields accuracy and precision. This one promotes different varieties of bevels, such as straight bevel, round bevel, and polygonal bevels. The 5 Axis is fitted with modern Computer Numerical Control technology hence its ability to boost the production rate among firms dealing in glass processing making it more efficient.

Application Fields: Multiple Applications in Different Sector

The CNC glass grinding machine is incredibly versatile, making it suitable for various applications across industries:

Architectural Glass: Designed for processing the glass used in curtain walls, partitions, and windows 5 Axis CNC glass beveling machine guarantees precise beveling of structural glass in buildings.

Fancy Glass: In cases where Home decoration and interior architectural glasses are required for custom-made Glasses, the Machine offers detailed Beveling of Mirrors, Shelves, and decorative panels.

Industrial Glass: The CNC glass grinding machine can also be applied for industrial glass by electronics, instruments, watches, chronometers, and other highly demanding fields.

Delivery and Service: Comprehensive Support

While buying the 5 Axis CNC glass grinding machine customers are provided with outright pre-sale and post-sale services. Now, BAINENG offers a series of supportive instructions, which includes the aspects of equipment installation, an operation handbook, and technical advice for those who are interested in a glass line automated system for the first time or for renewing their equipment. The company also avails after-sales services similar to a fallback in case of any complications or faults with the system.

Conclusion

The 5 Axis CNC glass beveling machine is the ideal choice for businesses seeking precision glass processing capabilities. With its advanced technology, high efficiency, and versatility, this machine is a powerful tool for improving your production line and enhancing the quality of your glass products. If you’re looking for a CNC glass grinding machine that combines performance, safety, and long-term durability, the 5 Axis CNC glass beveling machine is the solution you need. With its user-friendly interface, precision craftsmanship, and extensive support, it will help take your glass processing capabilities to the next level.