GLASS V GROOVE MACHINE Explained: What You Need to Know?

Exploring the World of Glass V Groove Machines:

As with any industry involved in constant change, glass processing is no exception, and in it; the GLASS V GROOVE MACHINE is more than a necessity. Therefore if you are in a position to improve your glass working skills, it’s important to understand how this machine works, what it offers, and how it can be used. In the following guide, you will discover critical information on these Machines and a guide on its working.

What is a Glass V Groove Machine?

A machine is a custom-built tool to perform a specific task of edge working on glass products. It is employed to produce V-shaped thin slots or through holes on the edges of glass panels which are very important in many fields like glass shelves, partitions, decoration, and so on.

Key Features:

• Precision Cutting: Presents precise V-shaped grooves with greater efficacy than most other tools and devices.

• Versatility: Suitable for all types of glass including the glazed and the laminated ones such as the tempered glass.

• Ease of Use: At times they come with easy-to-use controls that enhance their operation.

Glass V Groove Engraving Machine:

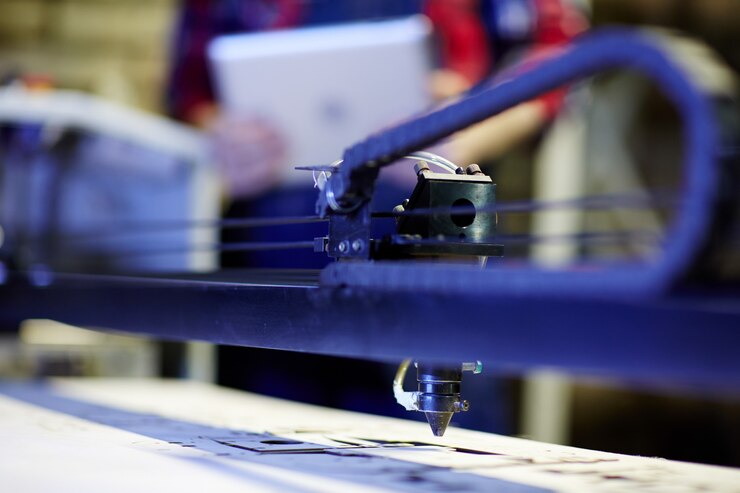

The GLASS V GROOVE MACHINE is the best tool for cutting and shaping glasses depending on the required design. This greenhouse machinery is suitable for producing fine patterns, lines, and stripes on flat glass, and this machinery is a single multipurpose unit. With a table that is designed to work and made with rubber covering, this machine also has a vacuum provision which makes sure that the glass is effectively positioned without having to fix it mechanically. They also feature an innovative design that enables easy placement of the glasses as can be seen below.

After that, the glass is installed into the CNC machine, and the entire carving process including the rough carving, the fine carving, and polishing is performed by the machine using the program stored in the system and including the tool change as well. This means that this automation increases efficiency and accuracy therefore it can be used for complex and simple designs. As in everything, those looking for a precise solution for accurate glass processing can find all this in this CNC machine, leaving requests for various glass processing.

Types of Glass V Groove Machines

Automatic Glass V Groove Machine: This machine is fully automated as the name implies and hardly requires the operator’s assistance. This is suitable for production lines that require speed and precision most especially when producing large quantities of products.

CNC Glass V Groove Machine: This machine employs state-of-the-art Computer Numerical Control (CNC) technology for better precision and flexibility in operation. It is ideal to be utilized for a more complicated and personalized glass job.

Portable Glass V Groove Machine: This machine is perfect for those who need to move the glass processing equipment from one site to another or do not have large space for work.

The Assorted Uses of Glass V Groove Machines

These machines play a vital role in various industries and applications:

• Architectural Glass: For achieving clean and professional edges commonly used around glasses of buildings and structures.

• Furniture: Applied also to manufacture glass shelves, tables, and other furniture.

• Interior Design: A definite requirement for glass panels that are to be installed for ornamental purposes or specially designed features.

Where to Buy Your Glass V Groove Machine?

When it comes to purchasing a GLASS V GROOVE MACHINE, consumers should target their search at BAINENG as the company is among the best in the market. We focus on the development of knowledge and technology in digital and high-accuracy cold processing equipment and products especially for hard and brittle non-metallic material. Specifically, we have invested heavily in research and development of this technology thus an ability to come up with innovative technology in this area.

Finally, being a high-tech enterprise, we make it a point to have each of the machines tested in professional institutions and CE certified. This is evident through our strong emphasis on quality and research where they have invested highly in their Research and Development section and so far have more than 30 patents to their name.

BAINENG is a supplier of GLASS V GROOVE MACHINE that will give off high performance and efficiency as well as utilize modern technology. A quick insight into their solutions may be found on their website and it would be wise to check them out.

Advantages of Operating a Glass V Groove Machine

Enhanced Precision: Ensures that groove sizes are accurate and of the right sizes, something which is paramount for quality glass products.

Increased Efficiency: Identify activities that otherwise will need a lot of manpower and time to accomplish and automate them to decrease the amount of manual work to be done and the time taken in the production process.

Versatility: Can accept all sorts of glass and the numerous processing requirements.

Improved Quality: Results in cleaner and more professional edges as compared to the manual methods.

How to Select a Proper Glass V Groove Machine?

When choosing the Machine, decide which type of glasses you have, how much of them you process daily, and what features you need in the equipment. Here’s a quick guide to help you choose:

• For High-Volume Production: A Machine with strong specifications is the best.

• For Custom or Complex Designs: A Machine is a tool required if one wants something accurate and versatile.

• For On-Site or Small-Scale Operations: You can get a Portable Machine that will meet your needs of having a portable machine.

Maintenance and Care

It is very important to maintain your Machines properly so that it would last long and function in an optimum manner. Follow these tips:

• Regular Cleaning: Help it to remain clean because dust and other debris can hinder the performance of the machine.

• Lubrication: Some of the preventive measures that should be taken are as follows; the moving parts should be lubricated to minimize damage.

• Inspection: Pay periodic attention to them as a way of identifying any signs of wear out or developing any kind of damage, then get it fixed as soon as possible.

Conclusion

A GLASS V GROOVE MACHINE is a valuable asset for any glass processing operation. By understanding its features, benefits, and applications, you can make an informed decision that enhances your glass working efficiency and product quality. Feel free to explore more about our products and services at BAINENG or contact us for personalized assistance. Whether you need an Automatic Machine, a CNC model, or a portable version, we have the right solutions to meet your needs.