How a CNC Engraving Machine Boosts Productivity in Manufacturing?

What is the Function of a CNC Engraving Machine?

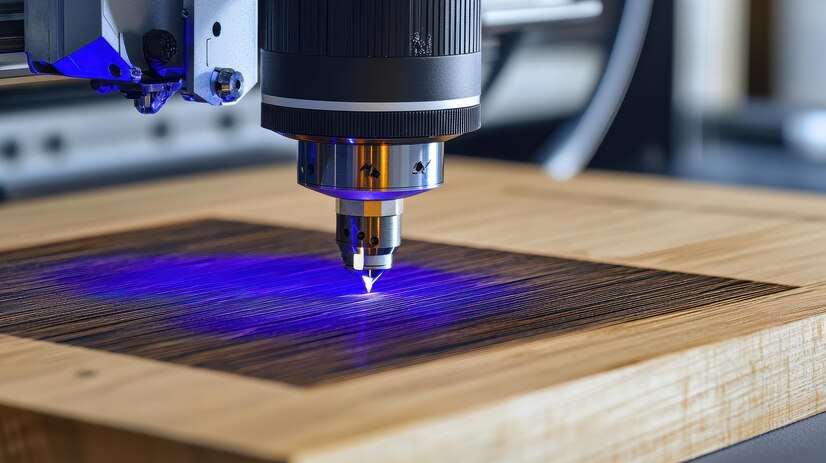

A CNC engraving machine also called a Computer Numerical Control engraving machine is a modern technology machine that operates the tools through commanding instructions. It is better than manual engraving since the power tool used in the process will implement the process for it, hence giving more accurate and similar work. These machines are also capable of making detailed designs on different types of materials including wood, metal, glass, stone, plastics, and acrylics.

These include CNC routers used in cutting plastics, and other soft materials, laser engraving equipment used in etching designs on woods, plastics, metals, and many others, and CNC milling machines used in cutting metals. There are also two types of CNC engraving machines namely the two and three-dimensional which are very helpful in creating designs that are complicated and unique. For instance, while using the CNC router, one can shape elaborate patterns on wood or make engravings of logos on metals.

CNC Engraving Machine Advance Features:

Such features make CNC Glass Engraving Machines the best for use by industries that require a lot of accuracy and durability of the equipment.

Equipped with an automatic contraction door which facilitates the loading and unloading of glasses.

The design was done in a way that it connects with a wireless hand remote that operates it making the use of gaskets unnecessary.

Pumps without vacuum aluminum freeze and blockage during engraving glass and contain several features like fade in fade out, timer, etc.

Patented cooling water sealing system: manifests the temperature control & avoids the problem of overheating

It is well suited to wide and deep groove engraving since it has a high-power spindle and overload gearbox which makes its processing efficiency to be very high.

Embarking on Your CNC Engraving Journey: Essential Steps

It can be thrilling if you’re just starting your CNC engraving projects you may admit to being a little intimidated. However, depending on the strategy that you apply, you can be able to maximize the use of the machine within a short duration of time. Here are the essential steps to guide you:

Choose the Right CNC Machine

It can be stated that when choosing the right CNC machine, it is necessary to take into account various aspects related to its functioning. It depends on the kind of material that you want to use and the type of engraving that you want to do. No matter if you are working with wood, metal, or glass, there are various CNC engraving machines for the kind of work that you are doing.

Master CAD/CAM Software

Understand how to apply CAD/CAM software in regarding your projects or models. This is the basic of CNC engraving and it enables you to design the pattern, format it, and send it to the machine.

Choose the Right Engraving to Stylize

Make sure that you are using the best CNC router bits or the best laser-cutting tools for your material. The appropriate equipment results in sharp and clear cuts on the objects.

Set Up Your Machine Correctly

This type of application should be run on an optimized machine, and set up correctly first before it can be used. Before cutting it is advised to spend considerable time on preparing the machine, specifically the cutting depth, cutting speed, and path of the tool.

Start with Simple Projects

One should have an initial practice and begin with simple designs before laying down patterns. You get well acquainted with the machine thus preventing you from making serious errors on major projects.

How Manufacturing Productivity is Increased with a CNC Engraving Machine?

CNC engraving machine is one of the best inventions in manufacturing industries since it enhances productivity as well as improves precision in the industries. Here’s how it revolutionizes operations:

Increased Efficiency

Machines such as Computer Numerical Control engraving machines eliminate some of the drudges that accompany the process of engraving. By increasing the speed and or maintaining stable output, the manufacturers can perform more tasks in a shorter amount of time thus increasing efficiency.

Enhanced Precision

While manual engraving the surface may not be engraved up to the expected quality as compared to the CNC machines which are accurate to the least detail. It reduces the chances of inaccuracies which often lead to a wastage of time as well as a lot of material.

Repeatability

When a design is programmed the machine can replicate it perfectly for as many numbers of pieces that are to be produced without compromising on the quality.

Cost-Effectiveness

Unarguably, the cash required to purchase a CNC machine may be high but the overall advantage of the machine in terms of time and money savings, minimal scrap, and almost zero error margin makes it a worthy investment in any production line.

Delivery and Service Offered by BAINENG

At BAINENG, we consider pre-sales and after-sales services as our major focuses to satisfy customers fully. Our team is committed to making your entire purchase process easy and fulfilling from selecting the right machine to using it and even after that. If you encounter any issues or have questions regarding the operation, we offer comprehensive services that include:

Tools and instrumentations for effective functioning of the equipment

A detailed functioning booklet that one can refer to when in a dilemma

Check by a specialist that your machine is optimized to achieve optimal performance.

Technical support as often as required for managing any issue which may be a problem in the operations.

These are the best options that one has to go for while looking for the right CNC engraving machine, and BAINENG becomes the obvious choice. Our machines are designed to be very accurate, strong, and fast in processing glass and other materials hence giving you excellent outcomes for your business.

Conclusion

A CNC engraving machine is a must-have tool for industries ranging from woodworking and metalworking to jewelry making and signage. Its precision, speed, and ability to work on various materials make it an indispensable tool for professionals and hobbyists alike. Whether you need custom engraving or industrial engraving, CNC machines offer the perfect combination of versatility and accuracy. Investing in the right machine can take your craftsmanship or production to the next level. Explore BAINENG of CNC engraving and discover how it can revolutionize your