Industrial Glass Polishing Machine: Perfect Glass Finishing

The industrial glass polishing machine forms the backbone of current glass processing. Automotive or architectural, there is a tremendous need for aesthetically appealing, smooth, and preferably polished and finely finished glass. Welcome the Glass Polishing Machine – precision that has been improved greatly as well as efficiency. Fujian Baineng Equipment such as the Precision Glass Engraving Machine is among the best and newest in the market. However, in this article, we will focus on everything that needs to be known about industrial glass polishing machines, their features, uses, and importance in different industries.

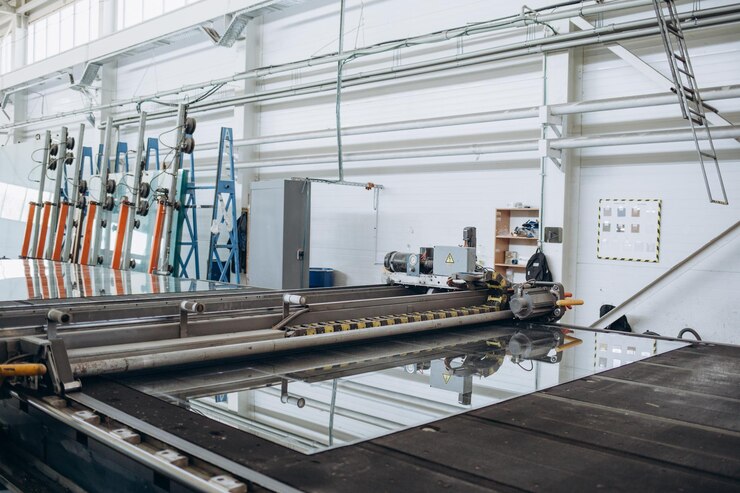

What is an Industrial Glass Polishing Machine?

An industrial glass polishing machine is sophisticated equipment, which is used to eliminate and smoothen irregularities on the glass surfaces, edges, and shapes. From automotive windshields to architectural walls and even optical glass applications, these machines deliver the best of both accuracy and speed. While simple polishing equipment is used for polishing glasses, Industrial glass machine is meant for large-scale high-speed operations for polishing glasses. Some of the most common changes are automatic glass polishing machines, Computer Numerical Controlled (CNC), and high-speed polishing systems which have all been developed to meet various needs of the various industries.

FEATURES OF INDUSTRIAL GLASS POLISHING MACHINES

High Precision Performance

These machines offer very high accuracy hence offering glass surfaces with no form of roughness at all. This documented positioning accuracy of +/- 0.01mm ensures that even the complex types of patterns or shapes to be polished can be achieved.

Versatile Polishing Modes

Ranging from plain flat glass to work on edges, to automotive and smartphone glass among others these machines can work perfectly well. The addition of rotary polishing and deep polishing just adds to their versatility.

Automated Control Systems

They are CNC numerical control machines, which means the best automation possession available in the market. By using batch processing of tasks, and other one-time operations, the chances are high that the work output will go up and there will be demands for physical work to be done.

Speed and Efficiency

The current machines can reach maximum speeds of 7000mm/s and therefore are well suited to high-speed production lines. No matter whether the work involved involves handling a few hundred Smartphone glass pieces or polishing large skyscraper panels, there is efficient work by default.

Uses of Industrial Glass Polishing Machines

Because the applications can be categorized in many areas, these machines are preferred in the industry. Some notable uses include:

Automotive Glass

These machines are utilized for polishing and making perfectly the windshield, side mirrors, and rear windows because of the durability and clarity that are crucial for safety and appearance.

Architectural Glass

As important components in skyscrapers or in-house rooms, architectural glass panels must possess great surface quality. For curtain walls, partitions, and even decorative etched glass, you find that machines help in polishing the surfaces.

Optical Glass

For lenses to better precision optical equipment, these machines bring attainable flatness and other physical features and properties of surfaces which are crucial for optical clarity.

Furniture and Home Appliances

Doors with glasses, mirrors, and kitchen glass panels are brightened up to look attractive as well as to give them a long-lasting value.

Advantages Associated with Industrial Glass Polishing Machines

Enhanced Productivity

The automation features minimize time wastage as well as minimize the exerted physical efforts leading to high production.

Improved Quality

Technological advancements result in the manufacture of polished and evenly uniform glass for different uses.

Cost Efficiency

In the long run, manufacturing a mechanical industrial glass polishing machine eliminates the added cost of employing many people and instance, material wastage.

Eco-Friendly Solutions

Most equipment incorporates energy-saving water or air cooling to ensure energy conservation and prevention.

How to Choose the Right Industrial Glass Polishing Machine?

There are factors that make up the glass polishing machine and they are the type of glass to be polished, the size of production, and the level of finish. Consider the following when selecting a machine:

• Type of Glass: What type of glass are you polishing automotive glass, architectural glass, or optical glass? Select a machine depending on your requirements and need not go for anything more complicated than this.

• Speed and Efficiency: How quickly exactly would you like the polishing process to occur? Fast-running equipment is particularly suitable for large-scale production.

• Precision Requirements: If you are involved in high-precision glass polishing then a CNC control machine is inevitable.

The Benefits of BAINENG Glass Polishing Machines

Our company, BAINENG, presents to you only machines that provide quality, innovative, and reliable products. Here’s what sets us apart:

• State-of-the-Art Technology

Our machines, ranging from our high-power lasers to our most advanced automation incorporate the latest technology to ensure that we meet market demands.

• User-Friendly Designs

The enhanced touchscreen interface helps the operators to operate and also monitor the condition of the machine.

• Long-Term Durability

The excellent structural features and underlying superior quality parts offer top-class performances which are further enhanced even in conditions of heavy operational pressures.

• After-Sales Support

In support services, we provide installation services, technical training services, and maintenance services.

Why Choose Us?

This position results from the idea that BAINENG has assembled years of experience exercises, scholarly research, and industrial knowledge to produce class-leading performance in glass processing. Regardless of your search for either a machine for industrial glass surface polishing or for architectural glass, engraving we are your best partner.

High-Quality Equipment

Quite rigorously, the TOP quality control measures are used as a vital approach to ensure that each of the machines meets the set industry standards.

Custom Solutions

Our company targets every business by providing industrial production solutions adapted to its needs.

Global Reach

Thus, our machines are trusted by clients around the continents.

Commitment to Sustainability

We fundamentally endeavor to attain greener industrial processes, by incorporating energy-efficient technologies in our plants.

The Significance of Accurateness in Glass Polishing

It is often said that precision is the soul of quality polishing and this is especially very true for glass. Whether the application is automotive glass polishing, architectural glass finishing, or optical glass polishing the precision of the process can limit the polished glass sheet’s appearance and functionality. This is one area of particular strength of CNC glass polishing machines because they can produce results of one micron or even less.

Conclusion

An industrial glass polishing machine is an indispensable tool for any business involved in glass processing. With advancements in CNC glass polishing, automated systems, and high-speed operations, these machines offer unprecedented levels of precision, efficiency, and versatility. Whether you’re polishing automotive glass, architectural glass, or optical glass, there is a solution tailored to your needs. For more information about glass processing machines and to explore our full range of glass polishing equipment, visit BAINENG.