CNC Glass Vertical Working Center

CNC Glass Vertical Working Center

Brief Introduction

Baineng VERTICAL GLASS WORKING CENTER MACHINE is a high technology machine which utilize the most latest numerical control system.It’s the best option for customers who needs high accuracy, high- functioning, high processing speed and easy applications. It’s the optimal solution for Edges,holes,notches, cutouts,polishing.etc.It’s the first choice for mass production for frameless shower doors,glass curtain wall.etc.

Our CNC Glass Vertical Working Center is a highly effective vertical glass processing center featured for the modern glass processing industry. This machine combines cutting, drilling, milling, and polishing functions, employing latest CNC technology and high-accuracy mechanical infrastructures to implement effective and accurate behaviours on different glass materials, meeting diverse processing needs.

Advantage

1.The machine employs a latest numerical control system that guarantees high effectiveness and easy functions, aligning customer demands for processing accuracy and premium quality.

2.Software: Engineering teams employed it, the software includes common layouts within the system. It simply includes the parameters, and the optimal route is generated automated.

3.5-Axis Construction: The machine features a 5-axis processing construction capable of handling inside/outside edging, drilling, milling, notching, and polishing in a single operation. Equipped with two spindle heads and a water-cooled electric spindle with a maximum output power of 7.5kW and a top rotating speed of 12,000rpm, it significantly enhances working efficiency while ensuring processing precision.

4.Vertical Design: This vertical-type machine contains less floor space, creating it useful for loading and unloading glass.

5. Functions: The machine can enhance as following, Inside/Outside Edging, Drilling, Milling, Cutting/Shape Cutting, Chamfering, Polishing

Application of CNC Glass Vertical Working Center

The machine is fit for all types of frameless shower doors, Sliding Doors, glass walls, etc. It is the optimal alternative to save labor and material costs, highly enhance working efficiency.

Prepare for Training and installation

1)Prepare 8pcs steel plates in size300*300*5mm.Put the plates to the bearing feet of machine.

2)Compressed air to 0.7-0.8MPA or Prepare Air Compressor.

3)Air Pipe in 10mm Diameter(Length will according to installation space).

4)Power Circuit:3*6² & 2*4²(Length will according to installation space)

5)Independent power control circuit breaker(3P45A)

6)A 10-20tons Jack Lifting(Adjust the level of machine).

7)Windows7 with 32bits computer

Key Features

- Versatility: Supports cutting, drilling, milling, and polishing functions, allowing one machine to complete multiple processing tasks and improve production efficiency.

- High Precision Processing: Equipped with a high-precision CNC system and high-quality tools to ensure accuracy and consistency in every operation.

- Vertical Operation: Vertical structure design saves floor space, making it suitable for various production environments.

- Automatic Functions: It offers the latest automatic control system with a one-click start, and planned path optimization. Further, it enhances the functioning procedures.

- Eco-Friendly Structure: It provides applealing touch screen layout permits the customers to conveniently to carry on processing and measures.

- Durability and Stability: It employs superior quality materials and parts that guarantee durability and stability for a prolonged time.

- Security: It uses various kinds of secure protective gadgets, it contains a laser protective cover and urgent stop button that enhance your safety.

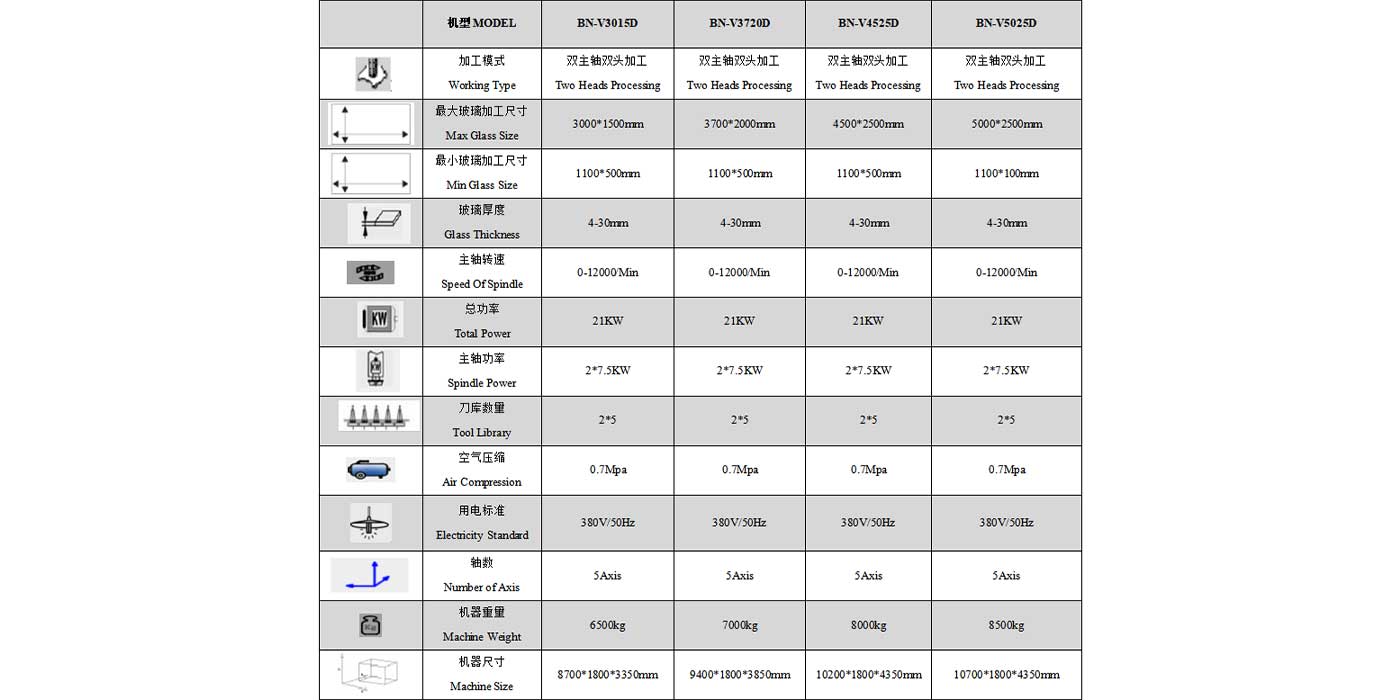

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 9kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

Application Fields

- Architectural Glass: It is empoyed for effective functioning of glass cutains walls, windows, and architectural walls.

- Fancy Glass: It is suitable for customized processing and highlighting the home decoration, architectures, mirrors and many more.

- Industrial Glass: It is beneficial for allowing the glasses to operate in different electronics, instruments, and other industrial fileds to ensure the high quality and accuracy.

Delivery and Service

We provide a more comprehensive pre-sales support and also after-sales services to guide the users if they face any problems or issues. We provide the sales services that include equipment fitting, functioning booklet, proper supervision, and technical support.

If you are exploring best Vertical Working Center, you must opt for our CNC Glass Vertical Working Center. Because it is excellent an effective, accurate, and durable glass processing machine . You will never regret after buying it.

Technical Parameter

Parts Advantage

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi | Japan |

| Bearing | NSK | Japan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

Parts shipping with machine

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | some pieces | M6*10,M6*20 |

| Thread seal tap | 1pcs | / |

| 3functions in one tool | 3pcs | / |

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.