CNC Vertical Glass Drilling and Milling Machine

CNC Vertical Glass Drilling and Milling Machine

The Baineng Vertical Glass Drilling and Milling Machine employs latest technology to acquire complicated tasks smoothly and accurately. This CNC Vertical Glass Drilling and Milling Machine offers an extraordinarily level of processing quality. In order to enable the users to acquire high standards with a minimal investment in CNC machinery.

Key Features

- Advanced Numerical Control System: The vertical CNC working center utilizes a numerical operation and control system, allowing dynamic management of each axis and precise speed control. This guarantees high accuracy in shaping and top-quality processed sheets, catering to both simple and complex designs.

- Effective and Precise Processing: It is majorly capable of automatically offering intricate drilling and milling functions on large flat glass. Once the glass is loaded onto the feeding rack, the machine executes the pre-programmed drilling and milling operations with high efficacy.

- Flexible Control System: The versatile control system demands the needs of different products, finishing all work automatically. This machine is optimal for processing structural glass such as frameless doors and glass curtain walls, with functionalities including drilling and milling.

- Space-Saving Vertical Design: The vertical structure is featured for easy loading and unloading of glass sheets, occupying less floor space. The machine’s main components are protectively covered, lessening obstructions and facilitating smooth glass sheet processing. Additionally, the design is advantageous for the coolant water system.

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 7.5kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

Applications

- Architectural Glass: It is best for accurate and optimal processing of different glass curtains walls, partitions, windows, and other infrastructural glasses.

- Fancy Glass: It is ideal for customized functioned and marking the home decoration, architectures, mirrors and many more.

- Industrial Glass: It is beneficial for allowing the glasses to operate in different electronics, instruments, and other industrial fields to ensure the high quality and accuracy.

Delivery and Service

We offer a more descriptive pre-sales support and also after-sales consultation to guide the customers . In order, if they face any problems or issues. We provide the consultation that include equipment fitting, functioning booklet, proper supervision, and technical support.

If you are choosing for best CNC Vertical Glass Drilling and Milling Machine, you must opt for our CNC Vertical Glass Drilling and Milling Machine. Because it is best an effective, accurate, and durable glass processing machine . It will solve your all problems and boost your enterprise growth.

BAINENG Software, developed by our IT team, features common patterns within the system, permitting you to simply input the parameters for automatic generation of the best route. The software is eco-friendly and convenient to know. By transferring CAD2000.dxf files to BAINENG software, it can automatically produces the necessary codes.

Operation process:

Steps for Using BAINENG Software

- File Import: Import your file.

- Select Lines: Select the specific lines you need.

- Set Parameters: Input the needed parameters.

- Update Parameters: Make any optimal adjustments to the parameters.

- Generate Codes: Automatically generate the codes.

Installation and Functionality

- Install BAINENG CAM Software: It must be compatible with Windows systems, this software permits users to draw different shapes in CAD and then automatically generate processing codes using CAM.

Proprietary MARCO Software

- Common Door Processing: Our proprietary MARCO software is designed for frequently used doors, such as Shower Doors, Overhang Doors, and Floor Hinges. It permits for the correct size to be filled in during processing, reducing the need for CAD drawings.

Scanning Code Recognition

- Small Batch Orders: We have created a scanning code recognition function particularly for handling small batch orders efficiently.

Applications

The machine is best for mass production of frameless shower doors, sliding doors, glass curtain walls, and more. This capability significantly lessens labor and costs, making it highly productive and cost-effective.

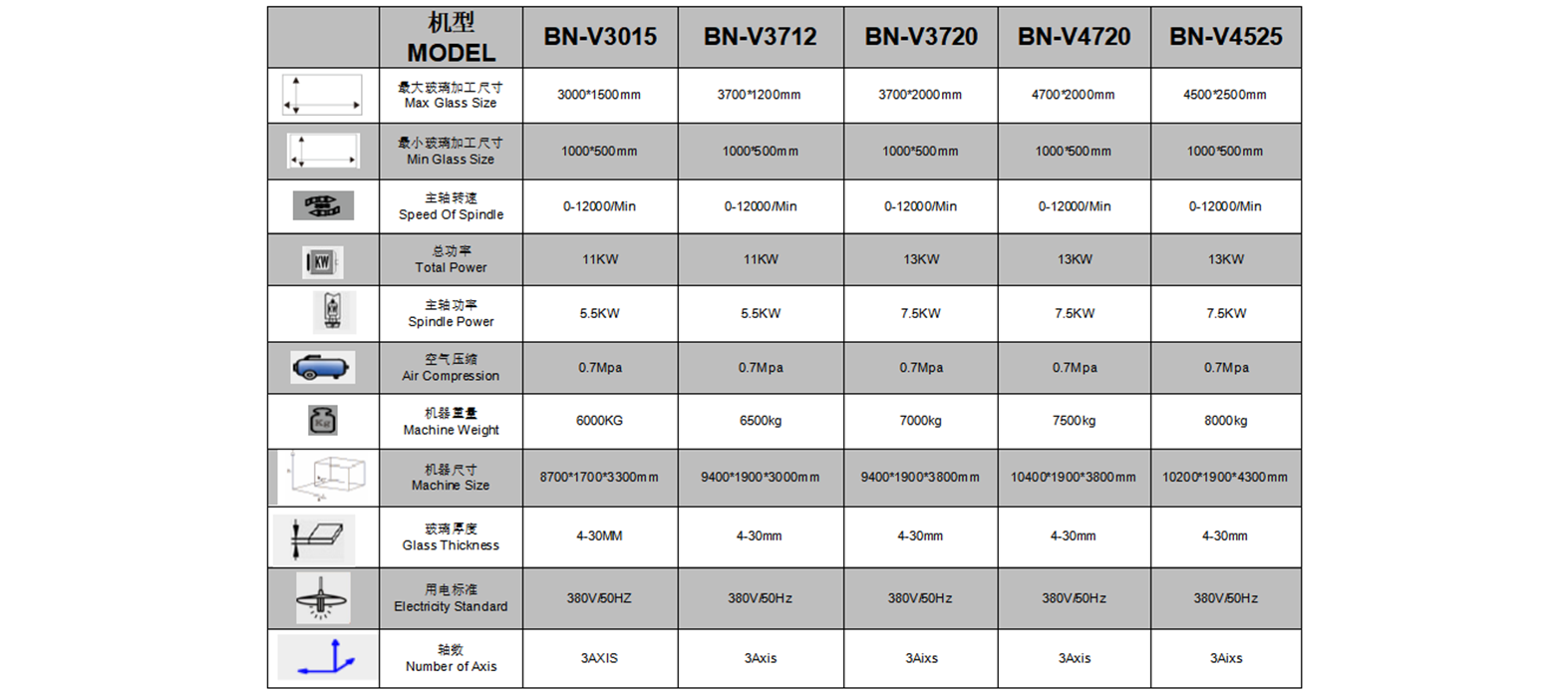

Technical Parameter

Components for machine

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi/Syntec | Japan/Taiwan |

| Bearing | NSK | Japan |

| Sliding Block | Hiwin | Taiwan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

| Spindle | Baineng | China |

| Synchronous Belt | / | China |

| Air Cylinder | Airtac | Taiwan |

| Synchronous Wheel | / | China |

| Water Pump | / | China |

| Steel Plate | Baosteel | China |

| Protection Cover | / | China |

Parts with machine

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | Some pcs | M6*10,M6*20 |

| Allen Nut | Some pcs | M10*20,M6*10,M6… |

| Thread seal tape | 1pcs | / |

| Water Pump | 1set | / |

| Transformer | 1set | / |

| Spindle water cooled machine | 1set | / |

| 3functions in one tool | 3pcs | Including milling,drilling,chamfering |

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.