Laser Glass Etcher Machine Technology in 2025

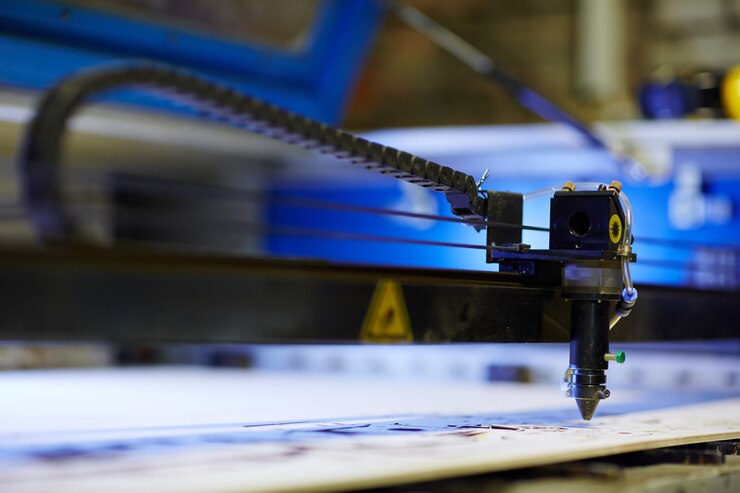

Glass Laser Machines: How Glass Engraving and Processing is Being Transformed?

Using the contemporary laser glass etcher machine has advanced the processing of glass and engraving in a highly efficient manner to suit various functions. Whether in manufacturing complex patterns on decorative wares or in mass production of glass parts, these machines offer unmatched opportunities for firms and clients. Some of the choices in this field include the Glass Laser Multi-Functional Machine and the Baineng Vertical Glass Working Center Machine, letting people FINISH the product according to their requirements with improvements and modern elements.

An Overview of Glass Laser Machines

Glass laser machines make use of the act of highly powerful lasers to engrave, etch, or process the glass substrates to precision. Such machines are meant for use on mirrors, metals, and other surfaces apart from metals. It is a noncontact method and the repeatability of the process is assured to achieve an excellent finish without fear of the article under treatment cracking.

As more consumers look for individualized glass items, including emblazoned advertising giveaways, artistic, and luxury adornments, as well as specialized utilitarian parts, laser devices for glass processing have become indispensable in various sectors from architecture and design to creation. A laser glass etcher machine is a piece of equipment that utilizes a focused light source in order to scribe, pierce, or inscribe glass surfaces. This process can also be referred to as laser engraving or laser marking because of the high level of accuracy assured by laser technology.

Full Pulse Glass Laser Multi-Function Machine

The Glass Laser Multi-Functional Machine is a unique device that is helpful when engraving complicated designs into glass and many other materials. Due to the elimination it performs and its accuracy, it has become the perfect solution for those companies that seek to gain time and avoid employing several workers to obtain equally excellent results.

Key Features:

• Multi-Material Capability: It can be engraved on the glass; mirrors, metals, etc., and is appropriate for various uses.

• High Speed and Efficiency: It scans an LED mirror in 2-3 minutes and uses about 1KW/ hour of electrical energy. This means lots of time is saved and efforts that would have been put into use are also reclaimed.

• Fine and Uniform Engraving: The laser results in fine dotting which makes patterns standardized and the designs are hard to be confused with any other.

• User-Friendly Operation: Because of its simplicity, this machine needs little training and gives standard results with the least variation.

How Does a Laser Glass Etcher Machine Work?

In laser glass etcher machine, the primary concept of operation depends on laser and material removal. Here’s how the process works:

Laser Beam Generation: A concentrated laser beam is produced by the machine with the help of the technology of CO2 or fiber laser.

Beam Focusing: The high precision is achieved to focus the beam onto the surface of the glass.

Material Interaction: The laser changes a layer of material on the surface by heating, vaporizing, or melting the latter.

Design Execution: The messages programmed into the architecture are as easily read and expressed into the glass in great detail.

This process is usually managed by CNC systems with the aim of being precise and accurate so that results can be replicated.

Advantages of Laser Glass Etcher Machine

Investing in a laser glass etcher machine brings a host of advantages:

High Precision

Laser technology provides high-quality accurate designs and can work perfectly well on intricate designs on fabrics.

Versatility

These machines can perform a wide variety of operations such as engraving a person’s name on a glass to laser marking metallic industrial products.

Durability of Markings

Laser etch designs do not wear off easily, are not easily destroyed, and maintain their crispness to an extent.

Eco-Friendly Technology

Utilizing laser etching cuts down on wastage and also utilizes less energy in comparison to other standard techniques.

Cost Efficiency

While they may cost a great deal of money at first, the savings that come from using these machines for servitude labor and efficiency improvement in the long run.

Laser Glass Etching tips!

Prepare the Glass Surface: Erase remnants of dust over the glass surfaces.

Use Protective Coatings: Taping of regions that must not be etched should be done although it requires a thin layer of taping.

Test Settings: Start with schematic test patterns and learn how speed, power, and frequency are optimized.

Regular Maintenance: Always clean the lens and mirrors to help the ray of light function effectively.

Why You Should Purchase BN Machine Laser Glass Etcher Machine?

When it comes to laser glass etching, we ensure to bring to you only the best in laser glass etching Services at BN Machine. All our machines are constructed with high precision, maximum efficiency, and high durability to suit both commercial and home use. If you are in the market searching for a laser glass etching machine for precision or a portable laser glass engraver, you are right here. Click here to see the entire publication of our products and learn how we can assist you in making your alluring design materialize.

This is a Few Reasons Why You Should Choose Baineng Glass Machines:

It has been established as a reliable brand for glass processing, which focuses on innovative solutions on the market. The company’s business belief of “technology innovation, quality first, sharing and win-win” is also reflected in its product portfolio by offering various components that enable higher productivity and improved measurement of glass processing.

Conclusion

Glass laser machines, such as the Glass Laser Multi-Functional Machine and the Baineng Vertical Glass Working Center Machine, are revolutionizing the glass processing industry. With their advanced features, high precision, and versatility, these machines cater to diverse applications, from decorative engraving to industrial production. Whether you’re looking to enhance your business’s efficiency or create intricate designs on glass products, Baineng range of machines offers comprehensive solutions. Invest in these innovative tools to achieve superior results, reduce labor costs, and stay ahead in the competitive world of glass processing.