Why Every Glass Manufacturer Need a Glass Working Machine?

Glass Working Machine: Transforming the Glass Processing and Fabrication Industry

Today the glass industry can be considered one of the most advanced industries for processing glass from manufacturing with regular tools to creating an extremely efficient and strong industrial process. Today, precision, speed, and innovation for the transformation process of the glass working machine are there. In this article, the author identifies the different types of glass machines, what they do, and their advantages. We also will include technical data that should be on any manufacturer’s radar, tips for how to better tailor your production process, and a connection to other articles to help build your knowledge base.

What is a Glass Working Machine?

A glass working machine is a specific type of tool chosen for cutting, bending, drilling, polishing, and heat-treating glass. These machines are very useful in the glass industry since they make their operations very smooth and effective while at the same time promoting efficiency through high-quality production. Regardless, they see applications in windows for homes, windshields for vehicles, and architectural glass panels, and all these applications benefit from these machines all through the processing line.

Who Needs Glass Working Machines?

• Enhanced Precision: Obtain the right cuts or edges.

• Increased Productivity: Eliminate the need for people to micromanage things, and automate repetitive work.

• Improved Quality: Ensure delivery of quality products, in that the fabrication does not compromise on material loss.

• Versatility: Ideal for a hefty range of glass products including mirror tempered glass and many more.

Glass Working Machine: Your Comprehensive Guide

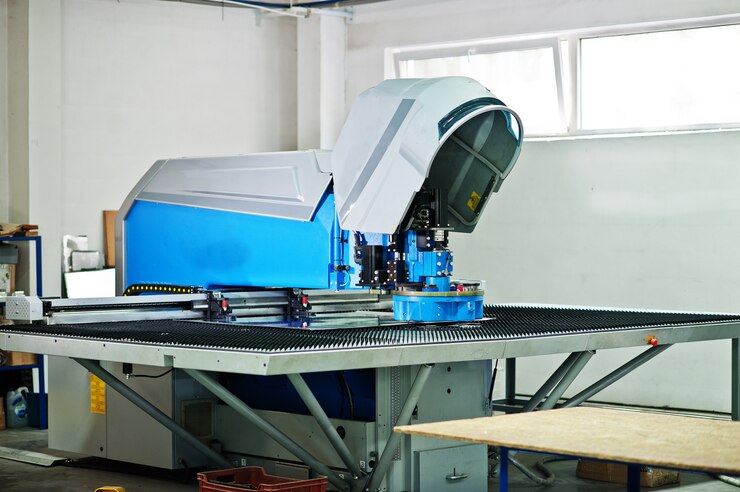

Our Glass Laser Multi-functional Machine is being specialized and developed to be able to fulfill the requirements of the glass processing industry. With the feature of cutting, engraving, and marking, this machine adopts the most advanced laser technique to offer precise and rapid working results on a wide range of glass. In fact, there is no structure, engraving, or cutting that these versatile machines cannot handle in infrastructure, features, or designs.

Key Attributes of the Glass Laser Multi-Functional Machine:

- Ideal for cutting, engraving as well as marking procedures and reduces costs associated with business/operations execution.

- Flexible to respond to varying processing needs with a lot of accuracy. With a high-intensity laser and an accurate command circuit within the device. It is made for the high accuracy and non-fluctuating nature of the work.

- Has a commodious laser source to enable operation without much hindrance. They provide enhanced path planning in dealing with complicated procedures simplistically.

- Glass working machine incorporates the latest advanced forms of automated control systems. Single-button launch and highly efficient routing improve the usability of the technology.

- The fact that the system has a touch screen makes it easy for everyone to use. They are constructed from the finest quality materials and various parts. It also covers laser protective and emergency stop buttons. They ensure the safety of users in the course of their operation.

Delivery and Service

Thus, we focus on the pre-and post-sale services and solutions. Our services include:

• Pre-sales Consultation: Specific recommendations on what types of equipment should be purchased.

• Installation Support: Provision of various forms of help from the initial stages of the setup process.

• Operational Training: To avoid hitches the company needs to provide a detailed user manual and give proper training.

• Technical Support: Quick and efficient repair and advice services.

Why Our Company’s Product-Glass Laser Multi-functional Machine?

Still, do not miss the opportunity to read the article if you need the most efficient glass-working machine. At our disposal, we are proud to present our Glass Laser Multi-functional Machine, which is characterized by excellent working quality. This multipurpose machine is meant to revolutionize your glass processing needs as it not only responds to your problems but also maps out your business’ success. For further information concerning our products, please visit our website with information concerning the various products that we offer. Experience the advanced approach to glass processing – let our solutions help you!

Advantages of Glass Working Machines

Operational Efficiency: Minimize time and labor by automating activities as a way of working.

Cost-Effectiveness: Minimize wastage of the material and make production cheaper.

Quality Assurance: The value obtained per batch must be the same as the previous batch.

Eco-Friendly: Reduce usage of energy with efficient models.

Scalability: Sustainability is completely on the card due to the extensive possibility of scaling production to match market requirements.

Uses of Glass Working Machines

Glass working machines are indispensable across various industries:

• Construction: Sliding, swinging, folding, rolling, glazed, storefront, rolling steel, skylights, partition walls.

• Automotive: Car windscreen, automotive rearview mirrors, car sunroof.

• Interior Design: Tables, shower glass, ornaments, panels.

• Electronics: Tablets, smartphone screens, and television screens.

What to Consider in a Glass Working Machine?

When investing in a glass working machine, consider the following:

Automation Level: Design options include the fully manual, semi-automated, and fully automated categories.

Precision: Mention parameters of machines with high cutting or grinding accuracy.

Durability: Make sure the parts of the machine you will build use premium quality materials for frequent usage.

Energy Efficiency: Choose energy-efficient ones in order to bring down the costs of operation.

User-Friendly Interface: Simplicity of control also implies that such machines will take a shorter time to train the operators.

How to Maintain Glass Working Machines?

Proper maintenance ensures the longevity and efficiency of your equipment:

Regular Cleaning: Minimize collection of dust and other dirt on the following structures.

Lubrication: Maintain smooth running parts well-greased.

Inspection: Examine bruises and deterioration of those parts of the machinery that incorporate the use of blades, belts, and motors.

Calibration: Use the scale at least once in a while to make an accurate calibration.

Software Updates: There is a need to update the software in CNC and automated machines frequently.

Trends for the Development of Glass Working Machines

The glass industry is evolving with the integration of advanced technologies:

AI and Machine Learning: Increase the ratio of automation and quality.

Energy-Efficient Models: Reduce environmental impact.

Smart Interfaces: Wearable and functional controls and also monitoring in real-time.

Customization Capabilities: Flexible systems to meet special production requirements.

Sustainable Practices: The recycling capabilities of glass waste.

Conclusion

Glass working machine is the backbone of modern glass fabrication, offering unparalleled precision, efficiency, and versatility. By understanding their types, benefits, and applications, you can make informed decisions that enhance your production capabilities. For reliable, cutting-edge glass working machines, visit BAINENG and explore our innovative solutions. Stay ahead of the curve in the glass industry with the right tools, strategies, and knowledge. Whether you’re cutting, grinding, or tempering, a glass machine is your gateway to excellence.